HOME Our Technology What is ‘PC’ (prestressed concrete)?

In the world of civil engineering and building construction, “PC” refers to “prestressed concrete.”

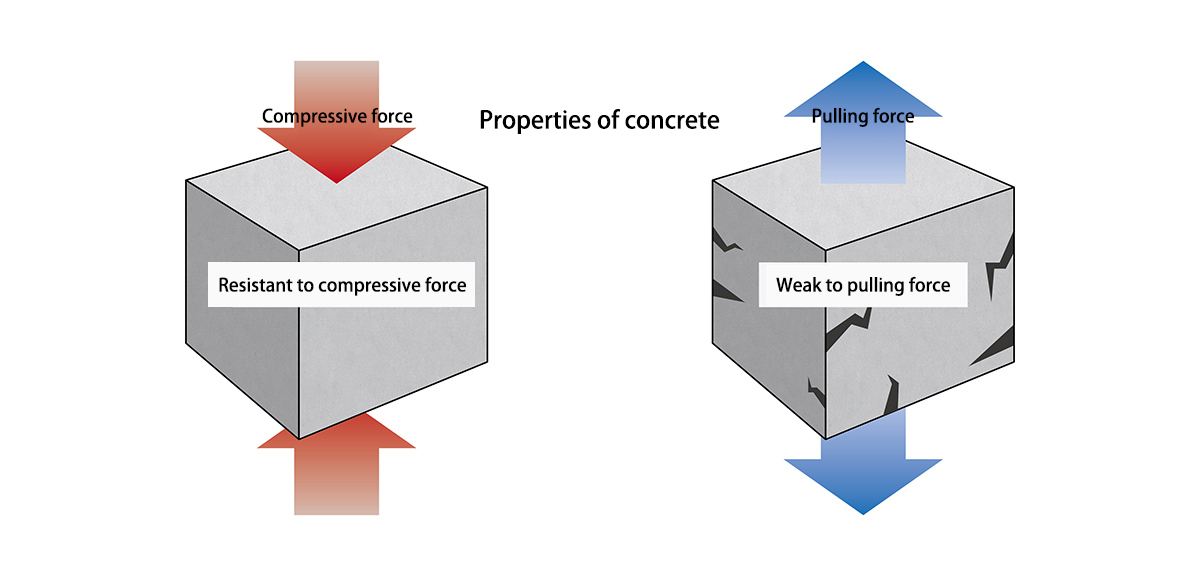

This term refers to concrete to which compressive stress is applied beforehand via tendons, and this PC technique is utilized in order to compensate for concrete’s biggest weakness.

Concrete has been used as building materials since ancient times, and, although it is resistant to compressive force, it is characteristically weak to pulling force and will break if significant pulling force is applied to it.

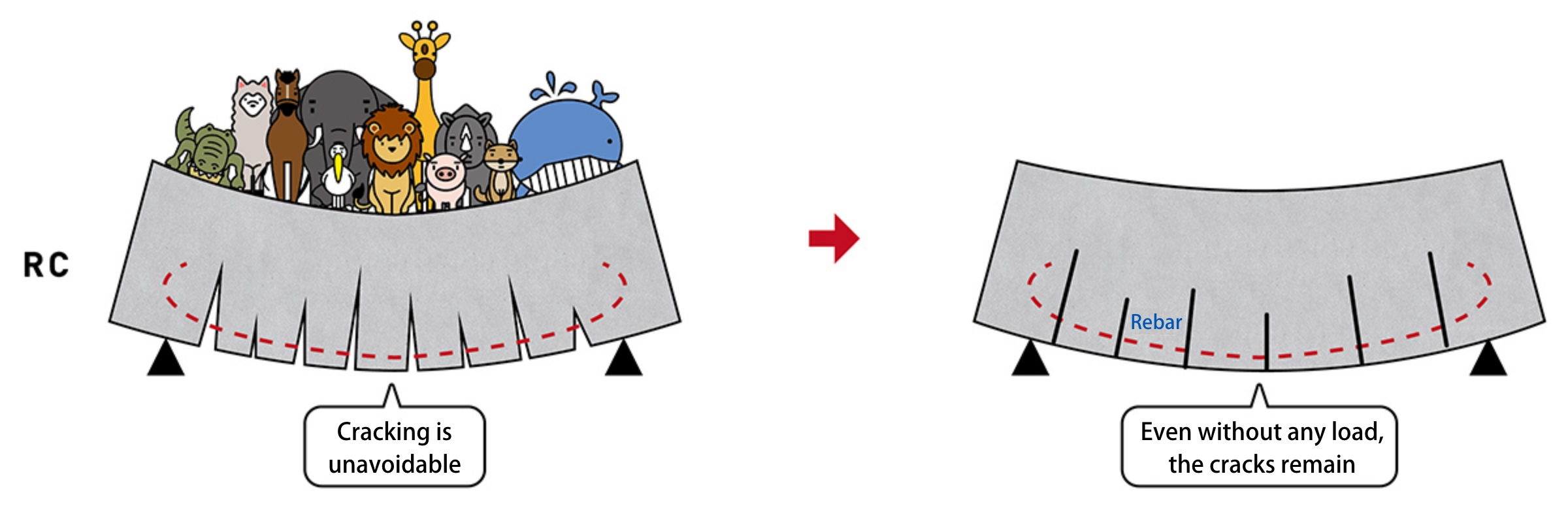

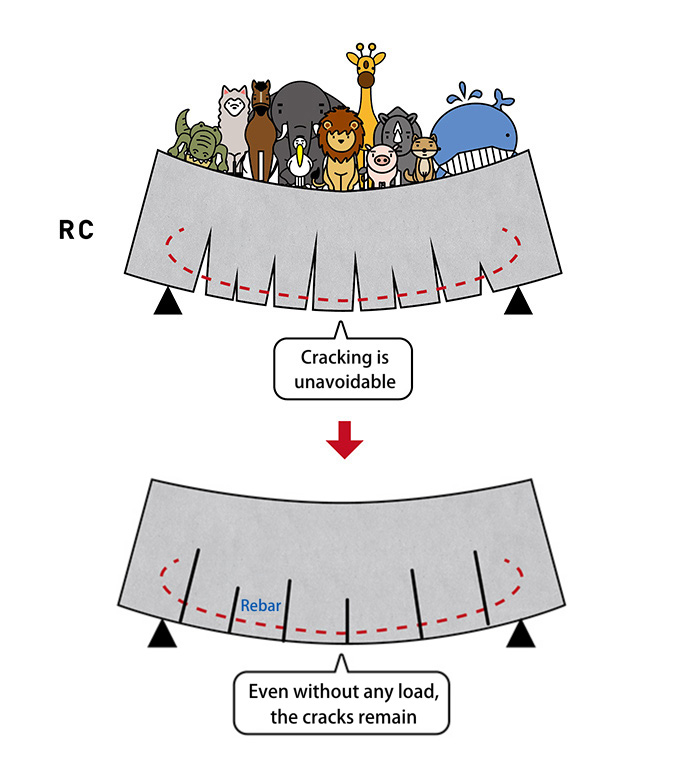

One method of compensating for concrete's weakness to pulling force is to use “reinforced concrete (RC).”

With reinforced concrete, rebar is incorporated in order to reinforce the concrete against pulling force; thus, when significant pulling force is applied, the rebar resists it, preventing breakage. However, it is unavoidable that the concrete will develop some cracks.

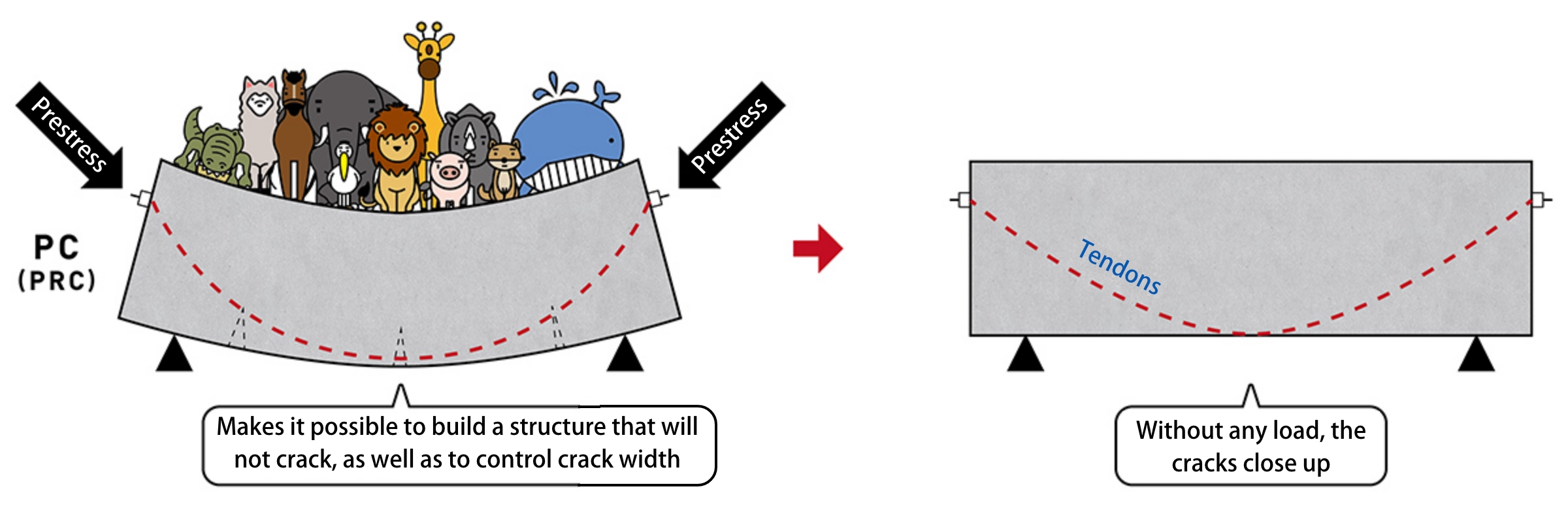

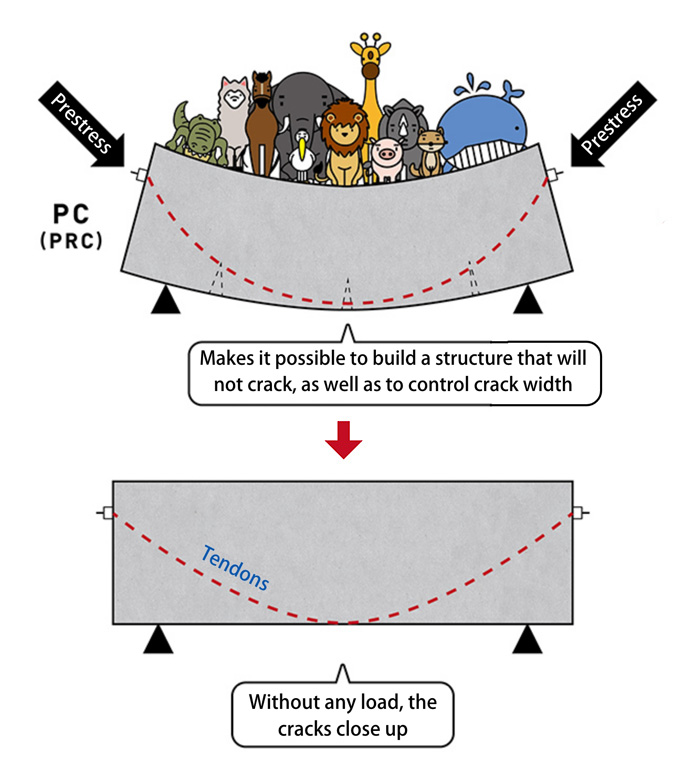

Thus, a method was developed whereby compressive stress is applied beforehand via the use of tendons to (prestress) concrete in order to prevent cracks from forming. With this method, concrete cracking can be arbitrarily controlled, even when significant pulling force is applied, by prestressing the concrete. This is “prestressed concrete (PC).”

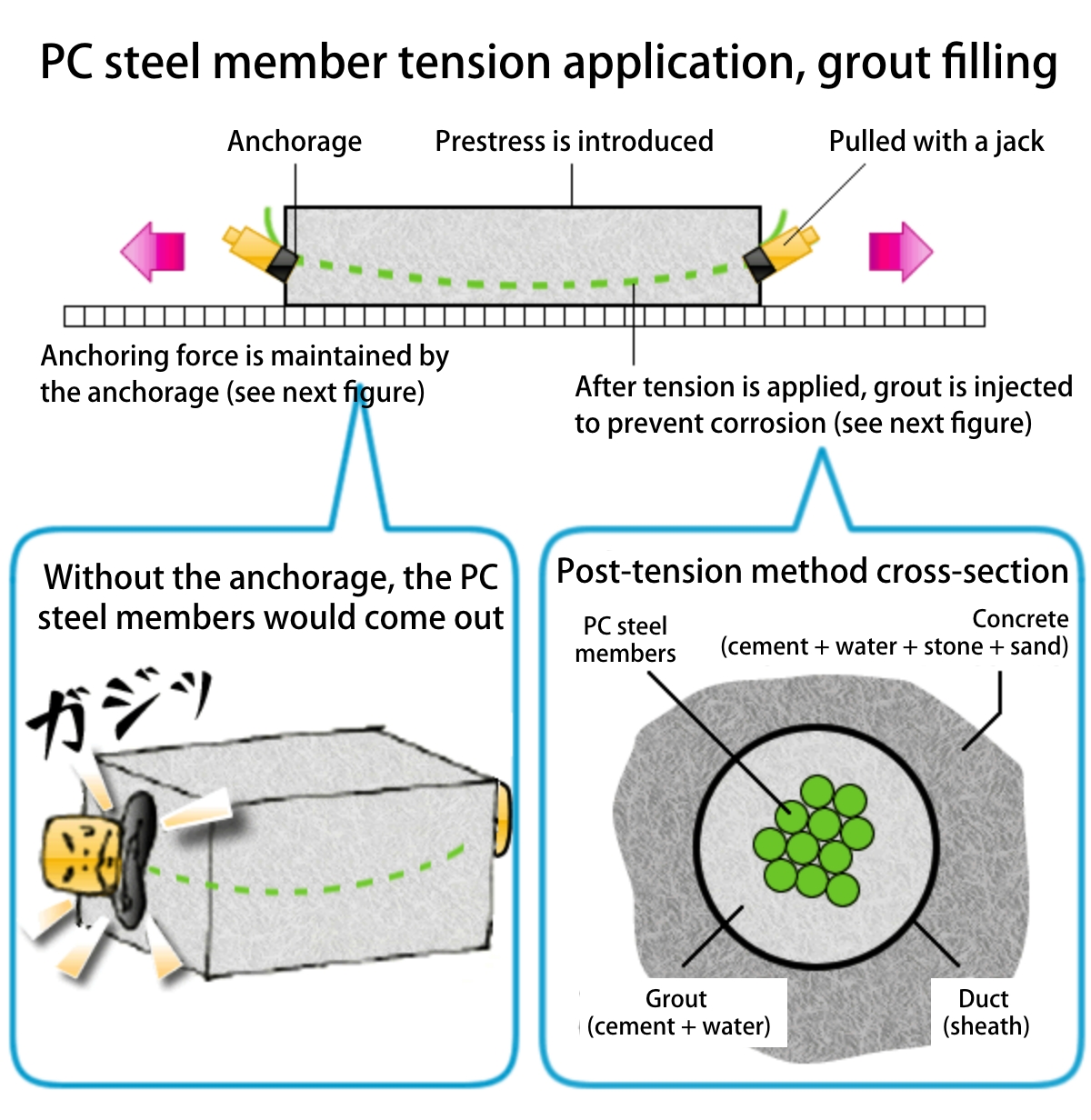

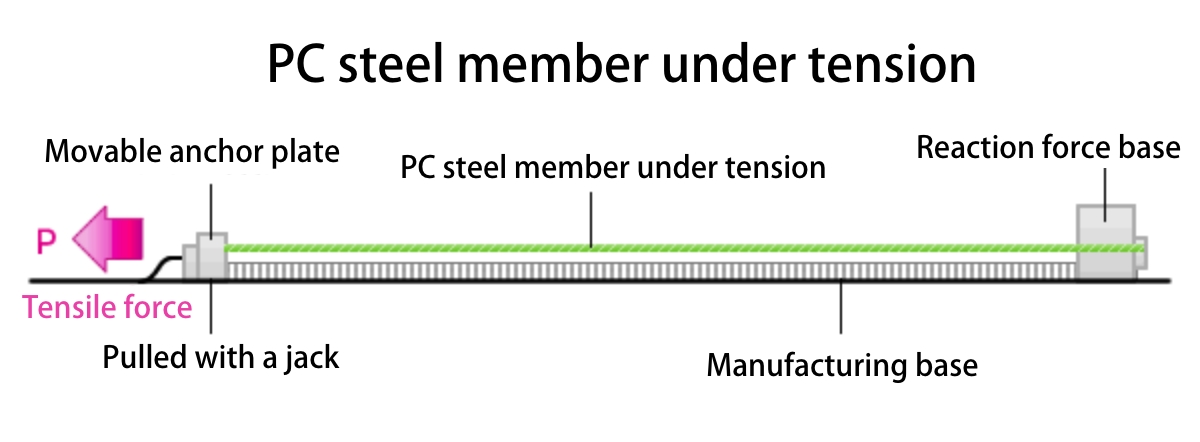

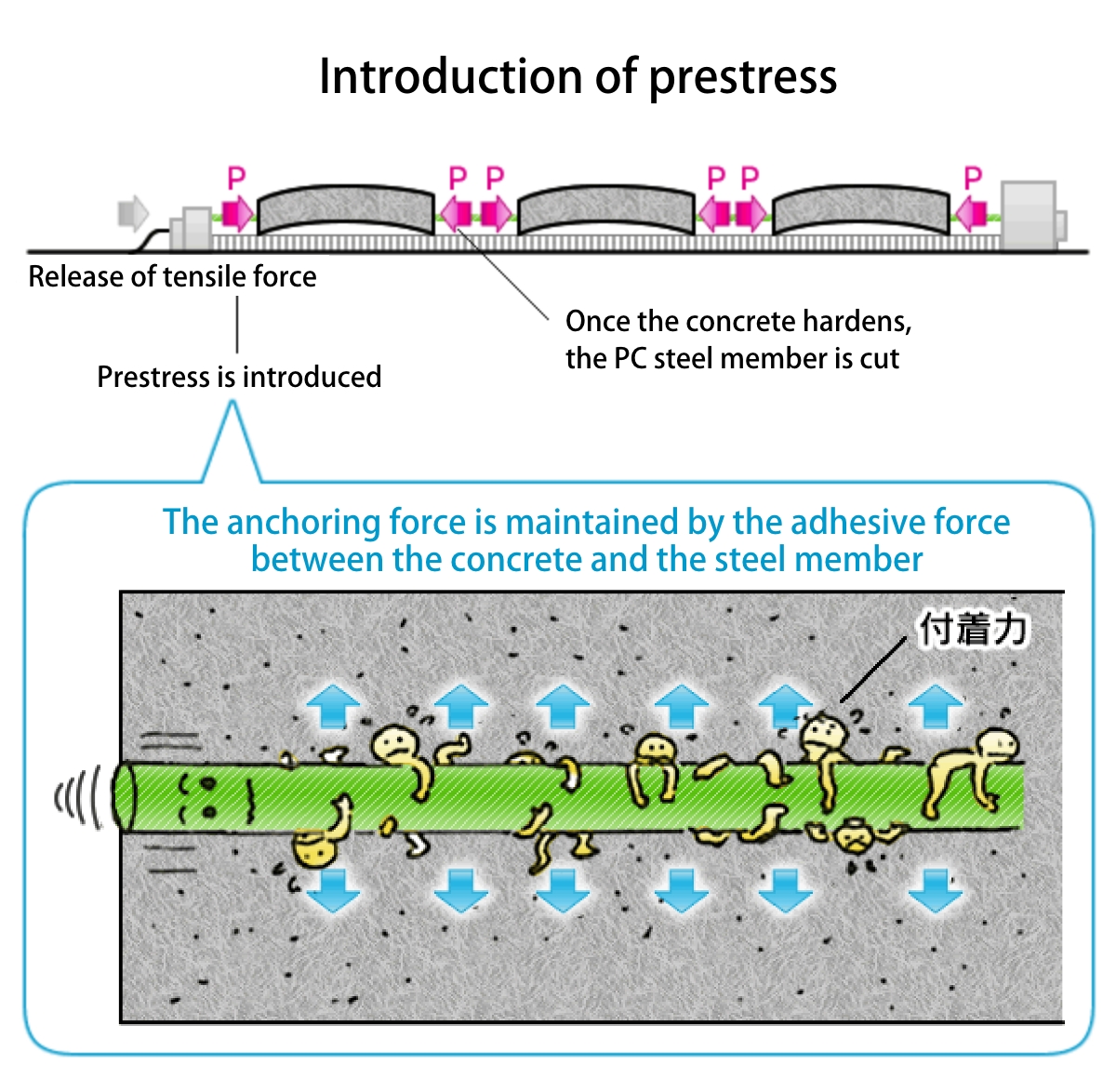

The goal of prestressing is to negate tensile stress in concrete due to load weight, and this is done by systematically applying compressive stress to the concrete in advance. And in order to apply this compressive stress to the concrete, a pulling force, i.e., tension, is applied to tendons (PC steel members). There are two methods for applying prestress: the pre-tension method and the post-tension method.

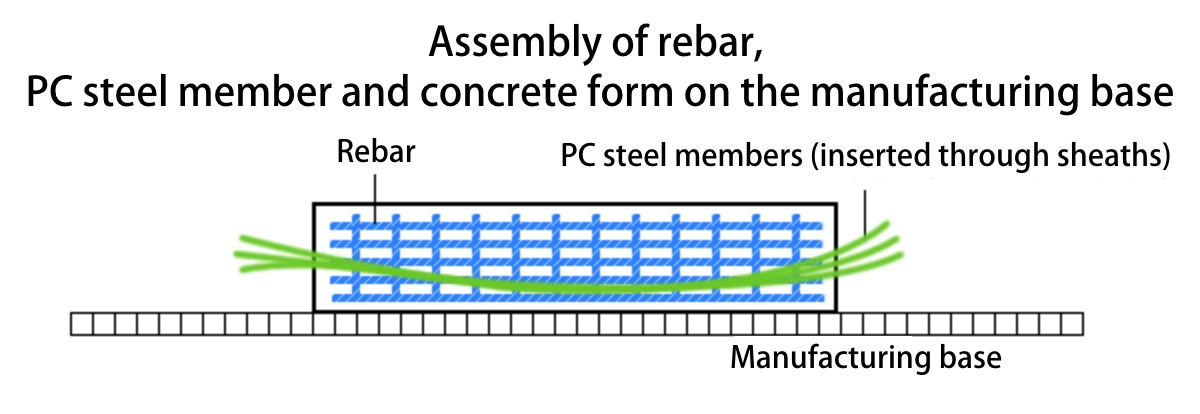

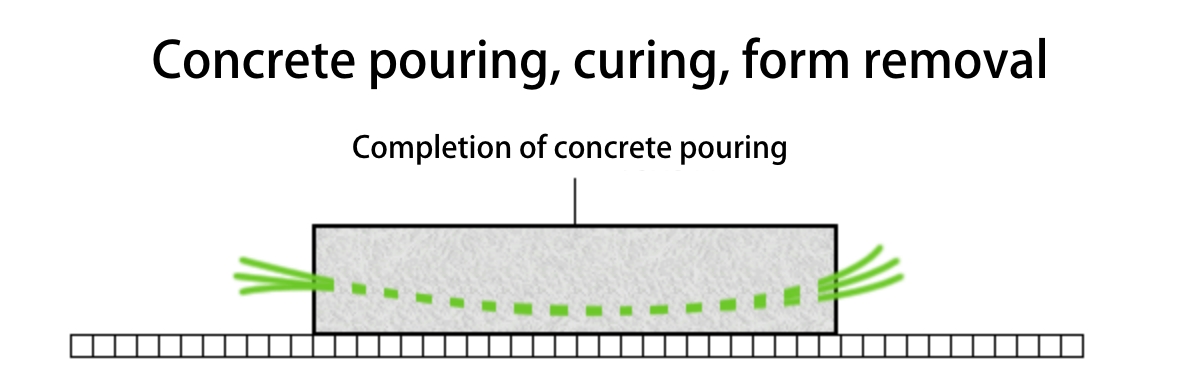

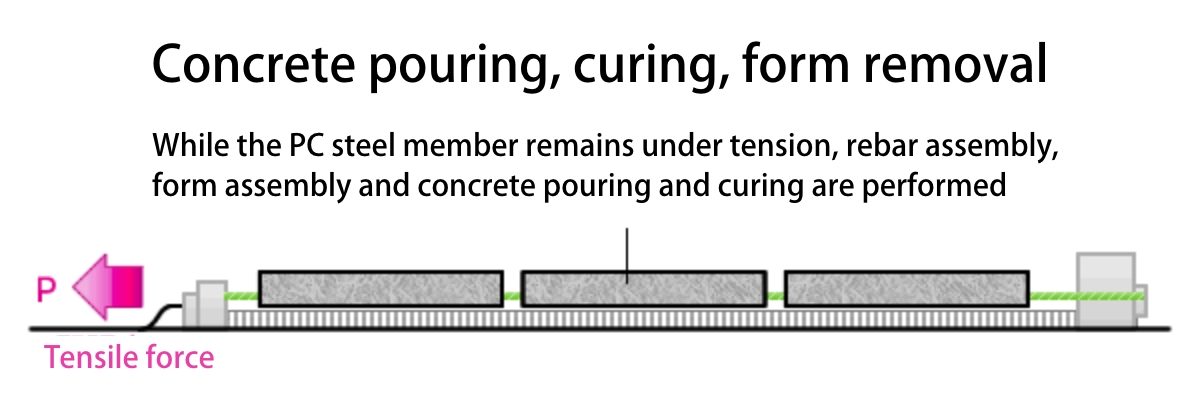

In the pre-tension method, PC steel members are first put under tension at a predetermined force and position; the concrete is poured into place and allowed to harden; then, the tension in the PC steel members is released, thereby prestressing the concrete via its adhesion with the PC steel members.

Given that limitations on manufacturing location due to equipment-related factors restrict the transportation of manufactured members, the pre-tension method is most commonly utilized with precast members that are relatively small and manufactured in large volume.

In the post-tension method, once the concrete member has hardened, tensile force is applied to the PC steel members inserted into ducts (known as “sheaths”) within the concrete, with this tensile force being maintained by the PC anchorage affixed to the ends of the PC steel members as prestress is applied to the concrete. Thus, the post-tension method is not limited to precast members but, rather, can be easily used for structures which are poured at the work site. Additionally, a key feature of this method is that it allows for great latitude in choosing the amount of tensile force to be applied.